Four Popular Types of Welding Procedures

The four main types of welding are: Gas Metal Arc Welding (GMAW/MIG), Gas Tungsten Arc Welding (GTAW/TIG), Shielded Metal Arc Welding (SMAW), and Flux Cored Arc Welding (FCAW)

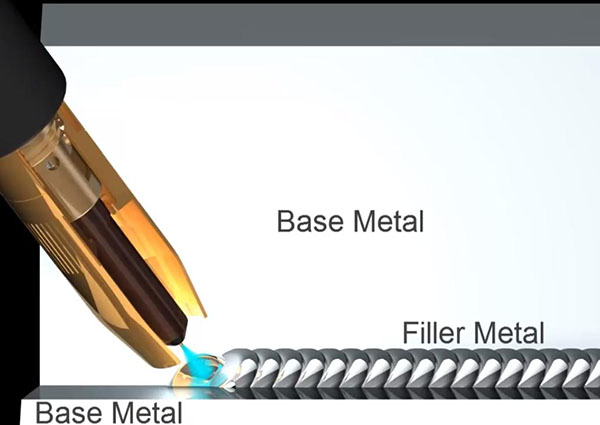

Gas Metal Arc Welding (GMAW/MIG)

Also known as Metal Inert Gas or MIG welding, this process uses a thin wire as an electrode. The wire heats up as it is fed through the welding instrument and towards the welding site. Shielding gas must be used to protect the weld from contaminants in the air.

Typically, this comes in the form of carbon dioxide, oxygen, argon or helium. This method is often used to work on metals such as stainless steel, copper, nickel, carbon steel, aluminum, and more. Of all the welding processes, this one is most popular across the construction and automotive industries.

Gas metal arc welding is believed to be one of the easier welding techniques to learn, which makes it a great area of focus for beginning welders. It also calls for minimal cleanup, offers high welding speeds and better control over thinner materials.

The GMAW/MIG welding process uses four primary methods of metal transfer:

Globular transfer produces a rougher weld bead due to metal droplet size and the propensity for spattering. This method is useful for welding thick metal plates in horizontal positions.

Short-circuiting works as the name implies – the welding wire contacts the base metal in a quickly repeated tapping method many times per second. Because little spattering is produced in the process, this method can be used in any welding position.

Spray Transfer transmits tiny droplets of molten metal in such a steady fashion that it maintains a steady-contact arc weld during the process. Even though this method produces little splatter, it is best to use on horizontal pieces that are thick and flat.

Pulsed-spray is very similar to Spray Transfer, but uses a high-low current pulse to allow micro-cooling periods. Because of this type of delivery, this process can be used on a wide variety of metal plate thicknesses, and in almost all welding positions. Note that when we use the term “cooling” when describing pulsed-spray, the moments of lower voltage that provide a cooler weld are still several thousand degrees Fahrenheit. It is only considered cooler relative to the high-voltage portion of the cycle. All welding uses extreme temperatures.

Gas Tungsten Arc Welding (GTAW/TIG)

This type of welding process, also known as Tungsten Inert Gas or TIG welding, is commonly used to weld together thin and non-ferrous materials like aluminum, copper, lead, or nickel. It’s commonly applied to bicycle or aircraft manufacturing.

Unlike other types of welding processes, TIG welding uses a non-consumable tungsten electrode to produce the weld. You will still need an external gas supply, usually argon or a mix of argon and helium.

This is considered one of the most difficult welding methods to master, and one that produces the most high-quality welds.

Because there is only a tiny area between the arc and the area being welded, it takes an enormous amount of precision and skill to complete. Welds born of this method are known to be extremely strong.

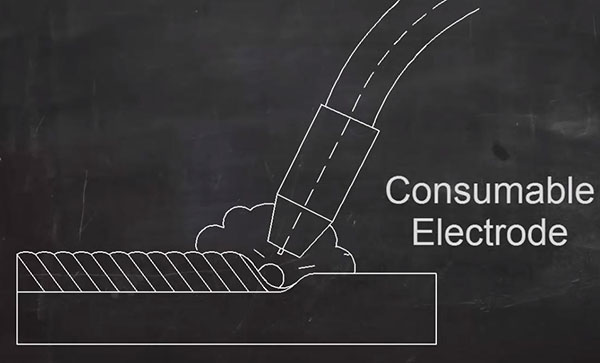

Shielded Metal Arc Welding (SMAW)

This type of welding process relies on a manual technique using a consumable electrode coated in flux. This method tends to be most popular among home-shop welders. This process is also more informally known as stick welding.

The nickname references the electrode used to weld the metal, which comes in the form of a “stick.” Because shielded metal arc welding requires minimal equipment, it’s one of the most low-cost processes around.

This type of welding does not require shielding gas and can be performed outdoors in the wind or rain. It also works well on dirt and rusty materials. That said, downsides do exist.

Stick welds don’t typically produce the best quality products. They are prone to porosity, cracks, and shallow penetration. In general, stick welds are less durable than what other types of welding will produce.

Flux Cored Arc Welding (FCAW)

This was developed as an alternative to shield welding. The semi-automatic arc weld is often used in construction projects, thanks to its high welding speed and portability. This method has many variables making it applicable in a variety of welding projects. Variables often depend on the model of welder being used, and what type of wire was chosen for the application.

The flexibility is broadened by the many operating angles, voltage levels, polarity used, as well as the speed of the wire feed. Due to the potential of faster welding speeds, the newly joined metal cools quicker. If the welding technician is using a flux cored wire, he or she must be on the lookout for porosity in the welded joint.

Flux Cored Arc Welding is best used in either outdoor settings or under industrial ventilation hoods, due to the amount of smoke and fumes created during the welding process.