Does solder conduct electricity ?

As a Chinese foreign trade company specializing in brazing alloys, BeiduoAlloys is committed to providing high-quality brazing materials and professional brazing solutions to our customers. In our work, we often receive questions from customers about whether brazing materials conduct electricity, as this is an important performance indicator of brazing materials.

The electrical conductivity of brazing materials depends on their chemical composition and structure. Typically, brazing materials are primarily composed of metals such as copper, silver, tin, and nickel, all of which have good electrical conductivity. Therefore, in general, brazing materials will have some degree of electrical conductivity.

Though all metals and a few metal alloys conduct electricity to an extent,there are some that are more conductive than others. What metal is the best conductor of electricity?

Silver

The best conductor of electricity is pure silver, but to no surprise, it is not one of the most commonly used metals to conduct electricity.

The wide use of pure silver has a couple of drawbacks. First, it tends to tarnish with usage,which will cause the unequal distribution of current.The second drawback is the most obvious—it is simply too expensive to run silver wire through a building—far more expensive than aluminum or copper.

Copper

One of the most commonly used metals to conduct electricity is copper. As a material, copper is pliable, easy to wrap or solder, which makes it the best choice when large amounts of wiring are needed. Copper’s core electrical function is related to the transmission of electricity and power generation. It is used in motors, generators, transformers, and bush bars. When properly installed, it is the safest and most efficient metal to produce electricity.

Copper is commonly used as an effective conductor in household appliances and in electrical equipment in general. Because of its low cost, most wires are copper-plated. You will often find electromagnet cores normally wrapped with copper wire. Copper is also used in microelectronic conductors, electric circuits and microprocessors because of its high conductivity and low resistance to joule heating. It is also used in mobile phones, TVs and computers.

Aluminum

Aluminum is yet another metal known for its high conductivity of electricity. Though by volume its conductivity is only 60% of copper, by weight, one pound of aluminum has the electrical current-carrying capacity of two pounds of copper. This makes it a very cost-efficient material, and because of this, it has increasingly replaced copper in some electrical-related applications.

Aluminum is used in long-distance power lines, high voltage electrical transmission and distribution on the utility grid; and, in the service drop, service entrance and building wire feeders. Its density and exceptionally lower cost make it a very smart choice for many large-scale electrical applications like electrical power cables, electrical power connectors, and even circuit breaker electrical contacts. Aluminum is often used in satellite dishes.

Therefore, different types of brazing materials may have differences in their electrical conductivity. For example, Metal Work Solder, which is primarily used for connecting metal components, typically contains metals such as copper, zinc, aluminum, and cadmium, all of which have relatively good electrical conductivity. As a result, this type of brazing material has excellent electrical conductivity.

By contrast, Electrical Solder, which is primarily used for connecting electronic components, typically contains metals such as tin, silver, and lead, all of which have even better electrical conductivity. As a result, this type of brazing material has superior electrical conductivity.

In addition, Solder Wire and Flux Kit are also common brazing materials, and their electrical conductivity is similar to that of the two types of materials mentioned above, and also depends on the electrical conductivity of the metals they contain.

When selecting brazing materials, it is important to consider the electrical conductivity requirements of the parts being connected as well as factors such as material strength, corrosion resistance, etc. because different types of brazing materials need to be selected for different applications in order to ensure reliable and high-performance connections.

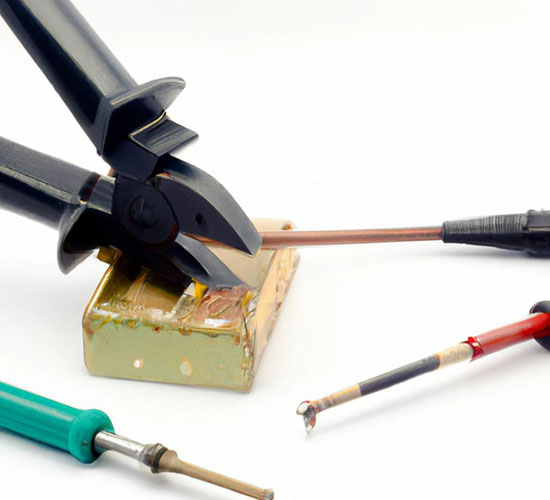

Moreover, it is also important to use appropriate tools and equipment when performing brazing operations to ensure the quality and efficiency of brazing. For example, when performing brazing operations, we need to use equipment and tools such as soldering irons, solder wire, flux, etc., and the quality and use of these devices and tools will affect the effectiveness and quality of brazing.

As a professional foreign trade company specializing in brazing alloys, we have rich experience and professional knowledge to provide suitable brazing materials and solutions according to the specific needs of our customers.